If we know anything by now, it’s that there is no one fool-proof way to solve climate change and reverse global warming. It is going to take multiple different approaches to make a difference. Coming up with new ways to help the environment is just what C02 Rail, a U.S.-based train start-up, has done.

C02 Rail’s new idea uses direct carbon capture which is a straightforward method to reduce the amount of carbon dioxide in the atmosphere. The captured carbon can then be utilized for other purposes or simply compressed and sequestered under the Earth.

C02 Rail has the idea to capture carbon directly from the air using its modified train cars. Currently, the methods used to capture carbon directly from the atmosphere require vast amounts of land and energy. C02 Rail and researchers from the University of Toronto have devised a new method that can tap into the existing rail network and capture carbon from the atmosphere while passenger and freight trains make their usual routes.

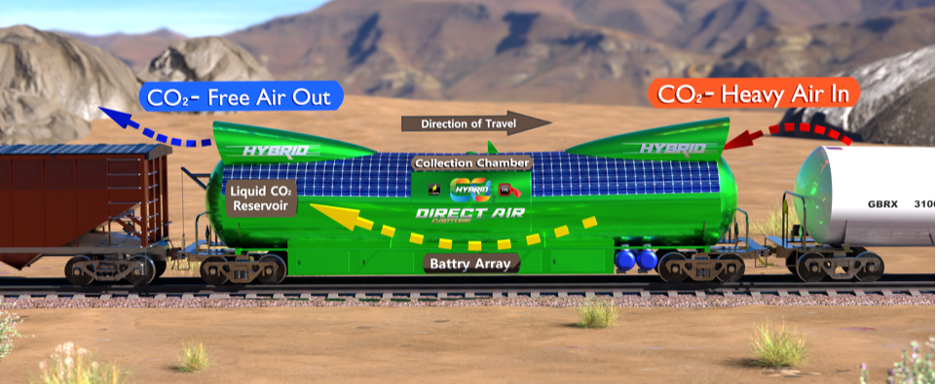

The researchers plan to use purpose-built train cars equipped with large vents to take in the air. This will be done at high speeds as the trains moves and eliminate the need for fans usually used by stationary direct carbon capture systems, saving significant amounts of energy. The train cars will be equipped with chambers to collect carbon dioxide, which will then be concentrated and stored in a liquid reservoir inside the train. The carbon dioxide-free air will be released back into the atmosphere from the underside of the rail car.

According to the founder of C02 Rail, E. Bachman, every 12 hours at crew change or fueling stops, the onboard C02 reservoir is emptied into a normal C02 tank car located at that station. When a large enough group of these tank cars have been filled, a train will be made and as much as 10,000 tons of captured C02 will be shipped into the circular carbon economy as a value-added feedstock of directly by rail to geological sequestration sites, Bachman said.

Efficiency is essential for this to work and researchers say that, at scale, it would run at about 93%, as a process. This means that for every 100 molecules of C02 captured out of the air, only seven would have been put out. For direct air capture, this is incredible and could be a game changer in climate solutions if it was rolled out on a global scale.

By using a regenerative braking system, the trains can convert friction into electrical energy, which can then be used to power the direct carbon capture process. Researchers estimate that an average freight train could remove more than 6,600 tons of carbon dioxide every year.

With a supply of power that has been sustainably generated, this method is not only environmentally friendly but also budget-friendly. According to Bachman, the projected cost at scale is less than $50 per tonne, which makes the technology commercially attractive and feasible.

Using this rail system could also deliver additional benefits such as freedom from zoning and building permits that are needed for large-scale capture methods. Over time, these purpose-built cars will become a regular feature of all train systems.